Loading

Search

▼ IoT Revolution On Horizon For Business, Private Life

- Category:Other

By Daisuke Ichikawa and Yu Komagata / Yomiuri Shimbun Staff Writers

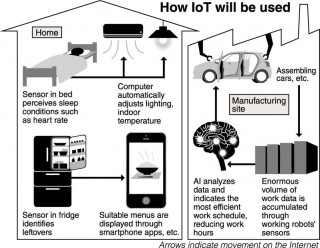

The Internet of Things, or IoT (see below), which connects various objects through the Internet, will make family life more convenient and production in factories more efficient. This new market has brought business opportunities for companies — it is no exaggeration to say IoT initiatives will influence the Japanese economy in the future.

When a person returns home, the locked door of the entrance automatically opens after it is confirmed that the person lives in the house. If they say “today’s menu,” a menu based on the food in the refrigerator is displayed on a screen. And when the person looks in the washstand mirror, it immediately ascertains their blood pressure and skin condition, and proposes things like a recommended vegetable juice or cosmetics.

These are scenes from a home utilizing IoT that has been featured in Panasonic Corp.’s showroom in the Ariake district in Koto Ward, Tokyo, since last summer. Sensors at various locations in the house are connected to electric appliances via the Internet. Blood pressure and skin condition are measured by a camera using cutting-edge technology.

Sony Corp. sells an electronic kit that enables people to realize IoT easily at ¥6,000 to ¥7,000 per kit. If an eraser-size sensor is attached to a lighting fixture, for example, its brightness can be adjusted through a special app.

IoT uses artificial intelligence and other technology to offer services be-yond a device’s conventional functions, not just manipulate electric appliances through the Internet.

Most of the IoT devices that major electronic manufacturers are working on for families provide various information via the Internet through sensors that recognize people’s images and voices.

The self-driving of vehicles is another form of IoT. Toyota Motor Corp. and other automakers are developing a system to avoid danger through sensors that recognize surrounding cars and obstacles. Technology is expected in the future that will enable a fully autonomous car — users would be able to tell their destination to a terminal installed in the vehicle and ultimately arrive there without touching the steering wheel.

Improving efficiency

If IoT becomes established in manufacturing plants, work efficiency could drastically improve. It could consolidate big data via the Internet, for example, about parts inventories and the demand for goods in each season. Artificial intelligence programs would decide the best working methods.

Last year, Fujitsu Ltd. connected the machines belonging to its subsidiary that manufactures telecommunications devices. This allowed it to instantly ascertain manufacturing conditions and how the numbers of parts have decreased.

The system made it possible to restock parts at the proper time. Fujitsu officials said the company’s production efficiency rose 20 percent as a result.

Mitsubishi Electric Corp.’s Nagoya Works also connected equipment for making machinery parts to the Internet, making it possible to control the entire assembly process. This resulted in shorter stoppages of assembly lines.

Japan faces a serious problem in that its population has begun to decline, which means a shortage of workers. Improving productivity is a common task for all industries.

“IoT will be the key to our company’s growth,” a Mitsubishi Electric official said.

U.S. and European companies are ahead of Japanese companies in their attempts to utilize IoT. The Japanese government feels a sense of crisis about the global situation, which is one reason it plans to boost its support for companies’ development of IoT.

Germany has promoted developments dubbed “Industry 4.0” by business, bureaucratic and academic circles since 2011. It has aimed to improve production efficiency as much as possible, to strengthen German companies’ international competitiveness.

In the United States, global giants have played leading roles in similar research and development projects.

Five companies in the United States, including General Electric Co., Intel Corp. and International Business Machines Corp., established a research institute for the purpose. More than 240 companies all over the world participate in the institute’s projects.

Their efforts have also stimulated emerging countries: China and India have set goals of strengthening their industries by utilizing IoT as national projects. South Korean companies, especially Samsung Electronics Co., are also enthusiastic about IoT.

Masashi Okawa, a research fellow of Mitsubishi Research Institute, said: “Though Japan started slowly at the initial stage, the government is becoming active. If [Japanese firms] can produce services that meet market needs, they’ll be able to catch up.”

Cybersecurity seen as biggest issue

The most important issue when it comes to the development of the Internet of Things (IoT) is defense against cyber-attacks, since such devices use Internet-based networks.

U.S. security experts ran an experiment last year to hack into a vehicle. The results shocked the auto industry: Experts were able to seize remote control after taking over its engine control system through a communications network, which is used for functions like car navigation.

Fiat Chrysler Automobiles, the vehicle’s maker, was forced to announce the recall of about 1.4 million vehicles.

According to a forecast by U.S. research company Gartner, there will be 25 billion IoT devices in use by 2020 — more than five times as much in 2015. This sharp spike is also expected to increase the number of channels that could be compromised.

Last year, the government adopted its Cybersecurity Strategy at a Cabinet meeting in a bid to strengthen security measures. But in an era of IoT when objects around the world are connected through the Internet, there are limits to what a single country can do to enhance security — and that makes international cooperation all the more crucial.

To move toward an IoT society, another important issue is the standardization of IoT devices and telecommunications. Currently, manufacturers’ factories have varying telecommunications standards and machinery control systems. More versatile systems and standards are considered to be ideal, since IoT becomes more efficient the more machinery devices are linked together.

Major U.S. semiconductor makers Intel Corp. and Qualcomm Inc. established an entity in February to jointly promote IoT standardization, after the rivals competed over the development of their own standards.

Japanese companies have traditionally focused on the enclosure of customers by providing in-house products with less versatility. But an association to promote IoT, established by Hitachi Ltd. and other companies, started devising national standards since June last year.

■ Internet of Things

The increasing number of devices in which a sensor can be installed is one factor behind the growth of IoT, as sensors are getting smaller and cheaper due to the spread of smartphones. The Japan IoT market is estimated at about ¥14 trillion in 2020, up from about ¥6 trillion in 2015.Speech

The Internet of Things, or IoT (see below), which connects various objects through the Internet, will make family life more convenient and production in factories more efficient. This new market has brought business opportunities for companies — it is no exaggeration to say IoT initiatives will influence the Japanese economy in the future.

When a person returns home, the locked door of the entrance automatically opens after it is confirmed that the person lives in the house. If they say “today’s menu,” a menu based on the food in the refrigerator is displayed on a screen. And when the person looks in the washstand mirror, it immediately ascertains their blood pressure and skin condition, and proposes things like a recommended vegetable juice or cosmetics.

These are scenes from a home utilizing IoT that has been featured in Panasonic Corp.’s showroom in the Ariake district in Koto Ward, Tokyo, since last summer. Sensors at various locations in the house are connected to electric appliances via the Internet. Blood pressure and skin condition are measured by a camera using cutting-edge technology.

Sony Corp. sells an electronic kit that enables people to realize IoT easily at ¥6,000 to ¥7,000 per kit. If an eraser-size sensor is attached to a lighting fixture, for example, its brightness can be adjusted through a special app.

IoT uses artificial intelligence and other technology to offer services be-yond a device’s conventional functions, not just manipulate electric appliances through the Internet.

Most of the IoT devices that major electronic manufacturers are working on for families provide various information via the Internet through sensors that recognize people’s images and voices.

The self-driving of vehicles is another form of IoT. Toyota Motor Corp. and other automakers are developing a system to avoid danger through sensors that recognize surrounding cars and obstacles. Technology is expected in the future that will enable a fully autonomous car — users would be able to tell their destination to a terminal installed in the vehicle and ultimately arrive there without touching the steering wheel.

Improving efficiency

If IoT becomes established in manufacturing plants, work efficiency could drastically improve. It could consolidate big data via the Internet, for example, about parts inventories and the demand for goods in each season. Artificial intelligence programs would decide the best working methods.

Last year, Fujitsu Ltd. connected the machines belonging to its subsidiary that manufactures telecommunications devices. This allowed it to instantly ascertain manufacturing conditions and how the numbers of parts have decreased.

The system made it possible to restock parts at the proper time. Fujitsu officials said the company’s production efficiency rose 20 percent as a result.

Mitsubishi Electric Corp.’s Nagoya Works also connected equipment for making machinery parts to the Internet, making it possible to control the entire assembly process. This resulted in shorter stoppages of assembly lines.

Japan faces a serious problem in that its population has begun to decline, which means a shortage of workers. Improving productivity is a common task for all industries.

“IoT will be the key to our company’s growth,” a Mitsubishi Electric official said.

U.S. and European companies are ahead of Japanese companies in their attempts to utilize IoT. The Japanese government feels a sense of crisis about the global situation, which is one reason it plans to boost its support for companies’ development of IoT.

Germany has promoted developments dubbed “Industry 4.0” by business, bureaucratic and academic circles since 2011. It has aimed to improve production efficiency as much as possible, to strengthen German companies’ international competitiveness.

In the United States, global giants have played leading roles in similar research and development projects.

Five companies in the United States, including General Electric Co., Intel Corp. and International Business Machines Corp., established a research institute for the purpose. More than 240 companies all over the world participate in the institute’s projects.

Their efforts have also stimulated emerging countries: China and India have set goals of strengthening their industries by utilizing IoT as national projects. South Korean companies, especially Samsung Electronics Co., are also enthusiastic about IoT.

Masashi Okawa, a research fellow of Mitsubishi Research Institute, said: “Though Japan started slowly at the initial stage, the government is becoming active. If [Japanese firms] can produce services that meet market needs, they’ll be able to catch up.”

Cybersecurity seen as biggest issue

The most important issue when it comes to the development of the Internet of Things (IoT) is defense against cyber-attacks, since such devices use Internet-based networks.

U.S. security experts ran an experiment last year to hack into a vehicle. The results shocked the auto industry: Experts were able to seize remote control after taking over its engine control system through a communications network, which is used for functions like car navigation.

Fiat Chrysler Automobiles, the vehicle’s maker, was forced to announce the recall of about 1.4 million vehicles.

According to a forecast by U.S. research company Gartner, there will be 25 billion IoT devices in use by 2020 — more than five times as much in 2015. This sharp spike is also expected to increase the number of channels that could be compromised.

Last year, the government adopted its Cybersecurity Strategy at a Cabinet meeting in a bid to strengthen security measures. But in an era of IoT when objects around the world are connected through the Internet, there are limits to what a single country can do to enhance security — and that makes international cooperation all the more crucial.

To move toward an IoT society, another important issue is the standardization of IoT devices and telecommunications. Currently, manufacturers’ factories have varying telecommunications standards and machinery control systems. More versatile systems and standards are considered to be ideal, since IoT becomes more efficient the more machinery devices are linked together.

Major U.S. semiconductor makers Intel Corp. and Qualcomm Inc. established an entity in February to jointly promote IoT standardization, after the rivals competed over the development of their own standards.

Japanese companies have traditionally focused on the enclosure of customers by providing in-house products with less versatility. But an association to promote IoT, established by Hitachi Ltd. and other companies, started devising national standards since June last year.

■ Internet of Things

The increasing number of devices in which a sensor can be installed is one factor behind the growth of IoT, as sensors are getting smaller and cheaper due to the spread of smartphones. The Japan IoT market is estimated at about ¥14 trillion in 2020, up from about ¥6 trillion in 2015.Speech

- April 5, 2016

- Comment (0)

- Trackback(0)